How does a Piezoelectric Generator Work? – Types and Characteristics

A major part of electrical engineering concentrates on new ways of generating electricity from other sources of energy around us, and another major part focuses on conditioning it. One novel kind of sensor converts mechanical energy directly to electrical energy without the need for rotational motion typical of a generator – the piezoelectric generator.

Since a piezoelectric generator needs no moving parts, it can be made very compact, reliable, and long-lasting; it also makes conditioning of the signal easier. There are many types of piezoelectric elements like shown below (source: piceramic), each element has a different shape and characteristics. Let us discuss the working of piezoelectric generator and its properties in detail in this article.

What is Piezoelectric Effect and How Does it Work?

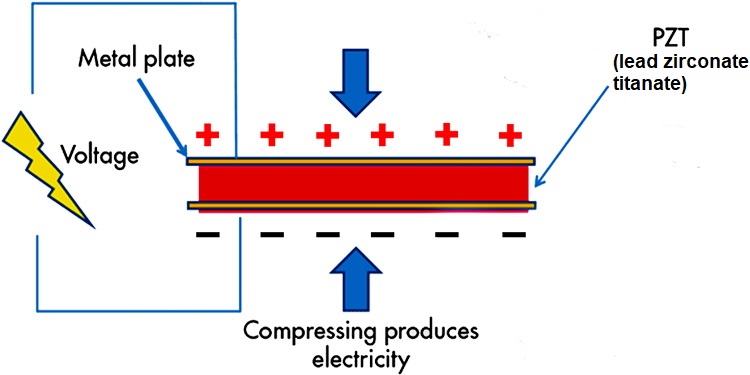

Piezoelectricity is the electricity generated because of the application of mechanical stress on certain materials, such as crystals (Quartz), ceramics (Lead Zirconate Titanate), and even some biological material such as bone and DNA.

The actual mechanism involves the generation of electric dipoles, which are two opposite charges separated by a small distance, which can be loosely compared to a bar magnet in the crystal structure.

When a force is applied to the crystal, small changes in the structure of the crystal lattice induces the formation of an electric dipole, which in turn produces a voltage across the faces of the crystal.

This voltage makes available a small amount of charge that can be used to power an external circuit. This effect also works in reverse, a voltage applied to a piezoelectric element will result in it deforming along a plane. This is how piezo buzzers and ultrasonic transducers work.

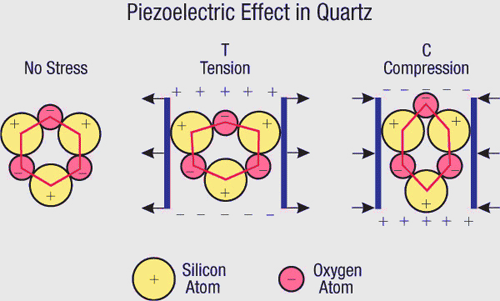

Let us look at a common piezoelectric material, quartz, in detail.

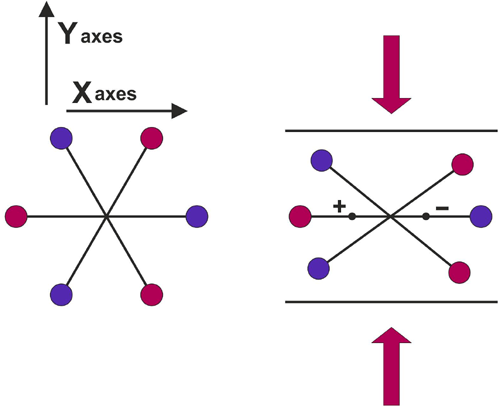

Quartz is a crystalline form of the compound silicon dioxide, which has a single silicon atom surrounded by four oxygen atoms arranged in a hexagonal pattern. Normally, each vertex of the hexagon has single oxygen or silicon atom in alternating order.

Each atom carries with it a small charge. In the case of quartz, the oxygen atom carries a negative charge, and the silicon atom a positive charge. Since the atoms are all arranged at an equal distance from each other, the charges are balanced on each vertex and there is no net dipole moment.

When the crystal is deformed along two opposite sides of the hexagon, the structure is flatted and now the distance between opposite vertices increases at the ends. This causes an imbalance of charges along a central axis, creating a small dipole moment.

This dipole moment induces a small voltage across the crystal perpendicular to the applied force.

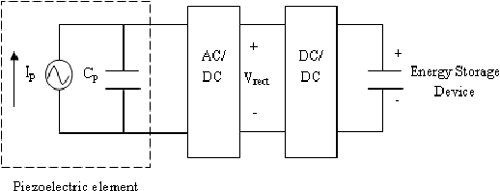

Output Characteristics and Signal Conditioning

The power source formed resembles a capacitor more than anything else, since only a discrete quantity of charge can be generated for every time stress is applied. The output is a high voltage low current pulse, which must be conditioned before use.

The conditioning circuit usually involves a rectifier with a low forward drop and a transformer to convert the high voltage to a lower usable voltage, and a storage element, usually a supercapacitor, to store the energy and a DC-DC converter to convert the energy to a usable form.

Now many chips exist that put everything in one small package, for example, the LTC3588 which needs very few external components and feature built-in power converter circuitry including power switches, which makes it easy to implement low-power Piezo energy harvesting systems.

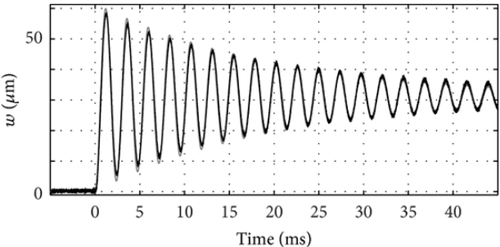

To generate electricity continuously, a constant oscillating source of mechanical energy is needed. This could be from vibrations from running engines or other mechanical equipment.

However, as the mechanical vibrations move away from the resonant frequency of the piezoelectric element, dielectric power losses increase. This can be countered by making the element with the same resonant frequency as the source of the mechanical vibrations which can be done by varying the dimensions.

The piezoelectric constant of a piezo crystal is given in units of C/N (coulombs per newton). This basically refers to the charge for every Newton of force applied. This value depends on the material, the crystal is made of, and the dimensions.

Common Piezoelectric Materials

Piezoelectric Materials can be found as both naturally occurring and artificially occurring elements. Some famous piezoelectric materials are mentioned below.

Naturally Occurring Materials:

Quartz was the first naturally occurring material that was discovered to exhibit the piezoelectric effect. Quartz is made of silicon oxide and has a piezoelectric coefficient of around 2pC/N.

Other materials like Rochelle salt (Potassium Sodium tartarate) and Sucrose (common sugar) exhibit piezoelectricity too.

Artificially Occurring Materials:

Ceramics are commonly used as piezoelectric elements. Some examples include Zinc Oxide, Barium titanate, and Lead zirconate titanate.

Piezoelectric Generators – Benefits And Limitations

The biggest advantage of piezoelectric generators is their size and versatility. Piezoelectric elements are usually very flat and flexible to a certain extent, so it’s easy to incorporate them into many things.

One common example is the incorporation of such a sensor in footwear. Every time a step is taken, the element is compressed and generates electricity. Though the amount of electricity generated is little, it can be conditioned and stored to do something useful later, like charging a phone or powering an emergency flashlight.

Multiple units can also be stacked to provide more output power, however, after a certain point, there are diminishing returns since they require more force to compress.

Since piezo elements harvest waste energy from devices, a piezo attached to a motor, for example, can harvest the energy from vibrations and lessen the noise since the vibration energy has been converted to electrical energy.

However, the biggest disadvantage of a piezoelectric generator is the limited output power. Since it’s very similar to a capacitor, to get a constant energy output, it has to be put through vibrations. The output is AC, so some signal conditioning is required to convert it to DC and to usable voltage and current levels.

Given these limitations and benefits, piezo elements are well suited to industrial environments with a lot of mechanical vibrations that can be used to power small IoT microcontrollers used to monitor equipment.

In conclusion, Piezoelectric generators use the piezoelectric effect to convert mechanical energy into electrical energy. They have low output powers and are suited to powering low current sensors from sources of mechanical vibration, and hence harvest energy that would have otherwise been wasted.